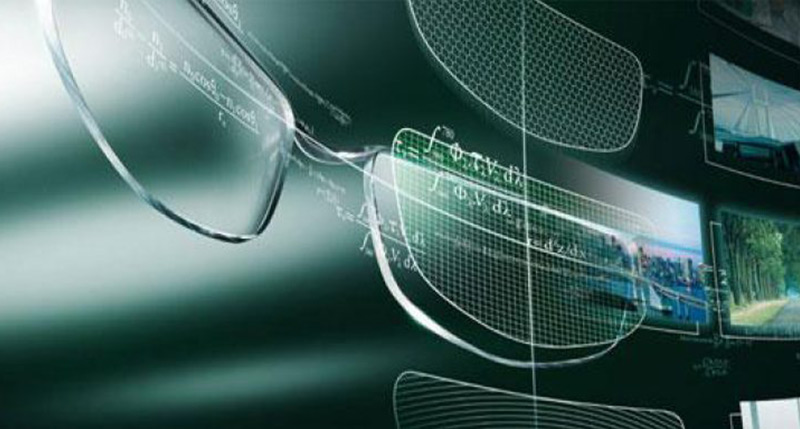

Digital Lens Surfacing relies on a controlled combination of lens design, precisely made molds, and manufacturing technology to create the perfect lens.

Digital lenses use a new design process for lenses which take into account reading posture, near zone placement, binocular vision, and sharper central focus. Today, a computer program calculates all of these factors into a lens that gives you best vision in all areas you look through. Advanced fitting systems also take into account head tilt, eye rotation and movement, and dominate eye.

Digital lenses use new manufacturing processes that allow an unlimited number of shapes and curves that can be produced on the surface of the lens. The tool used in this process is much more accurate and controlled, leading to a more precise lens surface. In the past, lenses were ground out on the back to the right distance prescription in multi-step process, known as “traditional” surfacing.

Digital surfacing relies on a controlled combination of lens design, precisely made molds, and manufacturing technology to create the perfect lens. Traditional surfacing also creates “rounding errors” which cause up to .06D of distance power errors. Digital surfacing gets that error down to within .01D of target power.

New digital lenses that utilize digital technology both for design and manufacture:

Give more precision – better Rx

Vary the reading corridor length to the size of the frame for best near vision

Give sharper central vision for distance viewing

“Widen” reading and intermediate zones

Take into account frame fit and position – they are customized for each frame and Rx